-

ฝากข้อความ : qiuwenjie@gaoboele.com

-

โทรศัพท์ : +86 -13418108841

ฝากข้อความ : qiuwenjie@gaoboele.com

โทรศัพท์ : +86 -13418108841

สถานีไฟฟ้าย่อยแบบกล่องคืออะไร?

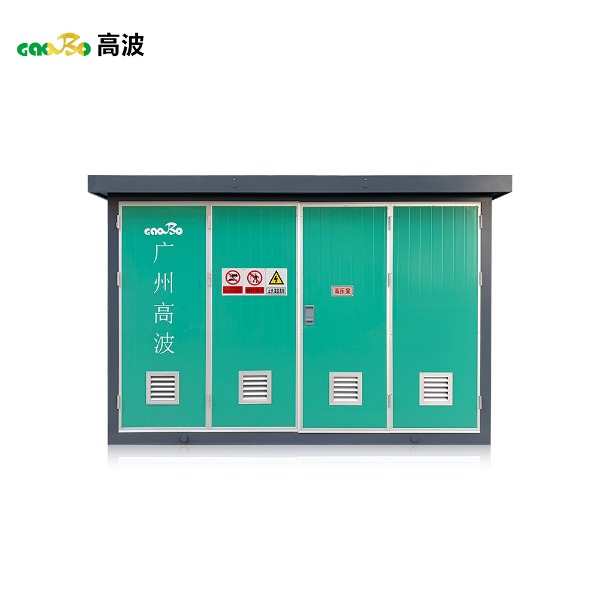

สถานีไฟฟ้าย่อยแบบกล่อง หรือที่เรียกย่อว่า "สถานีไฟฟ้าย่อยแบบกล่อง" เป็นที่รู้จักในระดับสากลในชื่อ "สถานีไฟฟ้าย่อยสำเร็จรูป" หรือ "สถานีไฟฟ้าย่อยขนาดกะทัดรัด" เป็นชุดอุปกรณ์จ่ายไฟฟ้าครบวงจรที่รวมเอาอุปกรณ์สวิตช์เกียร์แรงดันสูง หม้อแปลงไฟฟ้า อุปกรณ์สวิตช์เกียร์แรงดันต่ำ อุปกรณ์วัดกระแสไฟฟ้า และอุปกรณ์ชดเชยกำลังไฟฟ้าเชิงปฏิกิริยา เข้าไว้ด้วยกัน โดยทั้งหมดได้รับการประกอบล่วงหน้าในโครงสร้างเหล็กปิดสนิท ป้องกันความชื้นและสนิม ตั้งแต่หนึ่งโครงสร้างขึ้นไป ณ โรงงาน ตามแผนผังการเดินสายไฟที่กำหนดไว้

กล่าวโดยสรุป มันคือ "สถานีไฟฟ้าย่อยแบบพกพา" ที่รวมและแยกส่วนการทำงานของสถานีไฟฟ้าย่อย การจ่ายพลังงาน การควบคุม การป้องกัน และการวัดค่าต่างๆ เข้าไว้ด้วยกัน

โรงงาน Gaobo Power Solution ผลิตสินค้าคุณภาพสูง ระบบจ่ายไฟฟ้าสมัยใหม่ สถานีไฟฟ้าย่อยแบบกล่อง และบริการที่ปรับแต่งตามความต้องการของลูกค้า

คุณสมบัติหลัก:

1. การบูรณาการและการแบ่งส่วนโมดูล: อุปกรณ์ทั้งหมดของสถานีไฟฟ้าย่อยแบบวิศวกรรมโยธาแบบดั้งเดิมจะถูกรวมเข้าไว้ในโมดูลที่เชื่อมต่อกันได้หนึ่งโมดูลหรือหลายโมดูล ส่งผลให้โครงสร้างมีขนาดกะทัดรัดและได้สถานีไฟฟ้าย่อยแบบ "สำเร็จรูปจากโรงงาน"

2. การติดตั้งใช้งานอย่างรวดเร็ว: หลังจากขนส่งอุปกรณ์มาถึงสถานที่แล้ว ขั้นตอนต่อไปคือการติดตั้งโมดูล เชื่อมต่อสายเคเบิล และทดสอบระบบ เพื่อให้สามารถใช้งานได้ทันที ระยะเวลาก่อสร้างสั้นลงกว่า 60% เมื่อเทียบกับสถานีไฟฟ้าย่อยแบบดั้งเดิม

3. การทำงานแบบปิดสนิท: โมดูลเหล่านี้ผลิตจากโลหะหรือวัสดุที่ไม่ใช่โลหะ (เป็นมิตรต่อสิ่งแวดล้อม) มีการออกแบบแบบปิดสนิท และมีระดับการป้องกันโดยทั่วไปอยู่ที่ IP23-IP54 ซึ่งช่วยป้องกันฝุ่น ความชื้น และสัตว์ขนาดเล็กไม่ให้เข้าไปได้อย่างมีประสิทธิภาพ ทำให้เหมาะสำหรับสภาพแวดล้อมกลางแจ้งที่รุนแรง

4. ขนาดกะทัดรัด: เมื่อเปรียบเทียบกับสถานีไฟฟ้าย่อยที่สร้างด้วยวิศวกรรมโยธาแบบดั้งเดิม ระบบนี้ช่วยประหยัดพื้นที่ได้ประมาณ 70%-90% ทำให้เหมาะอย่างยิ่งสำหรับพื้นที่ที่มีทรัพยากรที่ดินจำกัด

5. สวยงามน่ามองและสอดคล้องกับสิ่งแวดล้อม: สามารถออกแบบโครงสร้างให้กลมกลืนกับภูมิทัศน์ (เช่น ใช้ลวดลายไม้หรือปกคลุมด้วยพืชพรรณ) ทำให้สามารถผสานเข้ากับสภาพแวดล้อมในเมืองหรือพื้นที่ธรรมชาติได้อย่างง่ายดาย

6. เคลื่อนย้ายได้และนำกลับมาใช้ใหม่ได้: เมื่อศูนย์กลางการใช้ไฟฟ้าเปลี่ยนแปลงไป สถานีไฟฟ้าย่อยทั้งหมดสามารถย้ายไปยังที่ตั้งใหม่เพื่อใช้งานได้อย่างต่อเนื่อง ส่งผลให้ได้รับผลตอบแทนจากการลงทุนสูง

แอปพลิเคชัน:

1. การกระจายพลังงานไฟฟ้าสาธารณะในเขตเมือง:การขยายโครงข่ายไฟฟ้าและการจ่ายไฟฟ้าให้แก่ผู้ใช้ปลายทาง เช่น ถนน พื้นที่อยู่อาศัย ศูนย์การค้า และสวนสาธารณะ

2. แหล่งจ่ายไฟชั่วคราว:ความต้องการใช้ไฟฟ้าชั่วคราวสำหรับสถานที่ก่อสร้าง งานอีเวนต์ขนาดใหญ่ การบรรเทาภัยพิบัติ ฯลฯ

3. วิสาหกิจอุตสาหกรรมและเหมืองแร่:ชุดจ่ายไฟอิสระสำหรับโรงงานหรือสายการผลิตในเหมืองแร่ บ่อน้ำมัน และโรงงานอุตสาหกรรม

4. ภาคพลังงานใหม่:ใช้เป็นสถานีเพิ่มแรงดันหรือสถานีรวบรวมกระแสไฟฟ้าสำหรับโรงไฟฟ้าพลังงานแสงอาทิตย์และฟาร์มกังหันลม

5. โครงสร้างพื้นฐานด้านการขนส่ง:จุดจ่ายไฟฟ้าแบบกระจายตามทางหลวง ทางรถไฟ สนามบิน และท่าเรือ

6. การปรับปรุงโครงข่ายไฟฟ้าในชนบท:แก้ปัญหาเรื่องระยะทางการจ่ายไฟที่ไกลและคุณภาพแรงดันไฟฟ้าต่ำในพื้นที่ชนบทได้อย่างรวดเร็ว.

ส่วนประกอบหลักและพารามิเตอร์ทางเทคนิคที่สำคัญ:

| ส่วนประกอบ | อุปกรณ์หลัก | พารามิเตอร์หลัก |

| ห้องแรงดันสูง | สวิตช์โหลดแรงดันสูง ฟิวส์ อุปกรณ์ป้องกันไฟกระชาก ตัวบ่งชี้สายไฟ | แรงดันไฟฟ้าที่กำหนด: 10kV, 35kV กระแสไฟฟ้าสูงสุด: 630A กระแสลัดวงจรที่ตัดได้: 16kA, 20kA ระดับการป้องกัน: IP3X |

| ห้องหม้อแปลงไฟฟ้า | หม้อแปลงไฟฟ้าสำหรับระบบจำหน่าย (โดยทั่วไปมีทั้งแบบแห้งและแบบแช่น้ำมัน) | กำลังการผลิตที่กำหนด: 200kVA, 400kVA, 800kVA, 1250kVA แรงดันอิมพีแดนซ์: Uk% = 4%, 6% ระดับฉนวน: ระดับ F, ระดับ H |

| ห้องสวิตช์เกียร์แรงดันต่ำ | เบรกเกอร์วงจรไฟฟ้าแรงดันต่ำ, เครื่องมือวัด, อุปกรณ์ชดเชยตัวเก็บประจุ, หน่วยตรวจสอบอัจฉริยะ | แรงดันไฟฟ้าที่กำหนด: 0.4kV กระแสไฟฟ้าสูงสุดของวงจรหลัก: สูงสุด 4000A ความสามารถในการชดเชย: กำหนดค่าไว้ที่ 20%-40% ของความจุหม้อแปลง |

| โครงสร้างปิดล้อม | โครงเหล็ก, แผ่นแซนด์วิช (พร้อมฉนวนกันความร้อน), ระบบระบายอากาศและทำความเย็น | วัสดุเปลือก: เหล็กเคลือบสี, สแตนเลส, อลูมิเนียม, วัสดุอโลหะ (GRC/SMC) | วัสดุที่ใช้ทำตัวเรือน: เหล็กเคลือบสี, สแตนเลส, แผ่นอลูมิเนียม, วัสดุอโลหะ (GRC/SMC) ระดับการป้องกัน: IP23D, IP54 ระดับความต้านทานการกัดกร่อน: C4 หรือสูงกว่า |

ข้อได้เปรียบที่สำคัญ:

1. ประสิทธิภาพการลงทุนสูง: ประหยัดค่าใช้จ่ายด้านวิศวกรรมโยธา การออกแบบ และการติดตั้งได้อย่างมาก ส่งผลให้ต้นทุนโดยรวมลดลงประมาณ 30%-50%

2. ระยะเวลาก่อสร้างสั้นมาก: ตั้งแต่การสั่งซื้อจนถึงการใช้งานจริง ใช้เวลาเพียงไม่กี่สัปดาห์ถึงหนึ่งเดือน ซึ่งช่วยเร่งกระบวนการจัดหาพลังงานได้อย่างมาก

3. ความปลอดภัยและความน่าเชื่อถือสูง:

ระบบล็อกห้าทาง: มาพร้อมกับระบบล็อกเชิงกลหรือไฟฟ้าที่สมบูรณ์เพื่อป้องกันการใช้งานผิดพลาด

หุ้มฉนวนโดยสมบูรณ์/หุ้มฉนวนบางส่วน: ส่วนที่มีแรงดันสูงสามารถใช้โครงสร้างแบบปิดที่หุ้มฉนวนโดยสมบูรณ์เพื่อลดความเสี่ยงจากไฟฟ้าช็อต

ระบบตรวจสอบอัจฉริยะ: มีระบบตรวจสอบออนไลน์เสริมสำหรับวัดอุณหภูมิ ความชื้น ควัน และการควบคุมการเข้าออก เพื่อการทำงานแบบไม่ต้องมีผู้ดูแล

4. เป็นมิตรต่อสิ่งแวดล้อมและสวยงามน่ามอง: การผลิตในโรงงานช่วยลดมลพิษและเสียงรบกวนในพื้นที่ และการออกแบบที่ยืดหยุ่นช่วยลดผลกระทบต่อทัศนียภาพของเมืองให้น้อยที่สุด

5. บำรุงรักษาง่ายแต่ละหน่วยทำงานอย่างอิสระ และงานบำรุงรักษาจะไม่รบกวนหน่วยอื่น ระบบตรวจสอบอัจฉริยะช่วยให้สามารถวินิจฉัยข้อผิดพลาดและตรวจสอบสถานะจากระยะไกลได้

6. มาตรฐานสูงและความยืดหยุ่นสูง: ผลิตภัณฑ์ในกลุ่มนี้มีมาตรฐานสูง และสามารถออกแบบตามความต้องการเฉพาะของลูกค้าได้

สถานีย่อยแบบกล่อง สถานีไฟฟ้าย่อยแบบกล่องอัจฉริยะเป็นผลผลิตทั่วไปของการวิวัฒนาการของระบบจำหน่ายไฟฟ้าสมัยใหม่ไปสู่การย่อขนาด ความอัจฉริยะ ความเป็นมิตรต่อสิ่งแวดล้อม และการผสานรวมด้านสุนทรียภาพ สถานีไฟฟ้าย่อยเหล่านี้แก้ไขปัญหาของสถานีไฟฟ้าย่อยแบบดั้งเดิมได้อย่างสมบูรณ์แบบ เช่น พื้นที่ขนาดใหญ่ ระยะเวลาก่อสร้างที่ยาวนาน และผลกระทบต่อสิ่งแวดล้อม และเหมาะสมอย่างยิ่งสำหรับความต้องการด้านพลังงานของการพัฒนาเมืองใหม่ การบูรณาการพลังงานแบบกระจาย และการติดตั้งอย่างรวดเร็ว ด้วยความก้าวหน้าของอินเทอร์เน็ตของสิ่งต่างๆ (IoT) และการมุ่งมั่นสู่เป้าหมายความเป็นกลางทางคาร์บอน สถานีไฟฟ้าย่อยแบบกล่องอัจฉริยะที่ผสานรวมการตรวจจับอัจฉริยะ การจัดการประสิทธิภาพพลังงาน และเทคโนโลยีคาร์บอนต่ำ จะกลายเป็นหนึ่งในส่วนประกอบหลักของเครือข่ายจำหน่ายไฟฟ้าในอนาคต